October 01, 2021

•Getting GMP Certified: How to Not Fail

Illustration by Stefan Gustafsson of www.stefangus.com.

If you had a crystal ball and could see into the future of cannabis and hemp, what would it look like?

Some assume a meteoric rise in money, fame, and power as if cannabis and hemp were unicorn startups finally having their day.

And while that may still happen, it remains to be seen just how meteoric the rise of these industries will be in the face of seemingly never-ending regulation and cumbersome restrictions. Luckily, there are other aspects of the industry where no crystal ball is needed. We can look to established industries for clues as to what the future holds. Hello food and beverages, pharmaceuticals, cosmetics, and more. Enter Good Manufacturing Practices.

And to those that fail to prepare, prepare to fail. But first, hemp history.

In 2018, the United States farm bill was passed, which defined the difference between a hemp plant and a federally illegal cannabis plant. This one bill launched the hemp industry in the United States and cultivation, extraction, and formulation of all kinds of consumer products began to take hold in the market. The “Green Rush” commenced and a subsequent boom and bust ensued. Without a federal licensing program, states were left to organize and institute independent licensing programs. Inevitably this led to an oversupply in the market and prices of refined material throughout the life cycle of the plant collapsed.

Most did not forecast the change in the market and those that were unable to adapt eventually failed. And now, as the ripple effects of legalization still impact the market, there is another industry earthquake lingering in the shadows...

The FDA has repeatedly issued warnings and further guidance regarding CBD and other cannabinoids. In the near term, it is strongly believed that the FDA will require hemp extraction facilities to be FDA registered and comply with Good Manufacturing Practices (GMP) ensuring the safety of consumer products either ingested or applied topically. The current market does not find GMP manufacturing practices a necessity and due to the dramatic over supply of refined material, price is more influential than quality in most brands’ purchasing decisions.

Those entering hemp from industries like alcohol and pharma know that this won't last. It is strongly believed the FDA will see CBD and other cannabinoids as ingredients and will shortly require all extractors to guarantee GMP manufacturing practices as they do from other established industries like food and cosmetics. The smart money is starting now, either when constructing new facilities or upgrading existing extractors to ensure compliance with GMP standards.

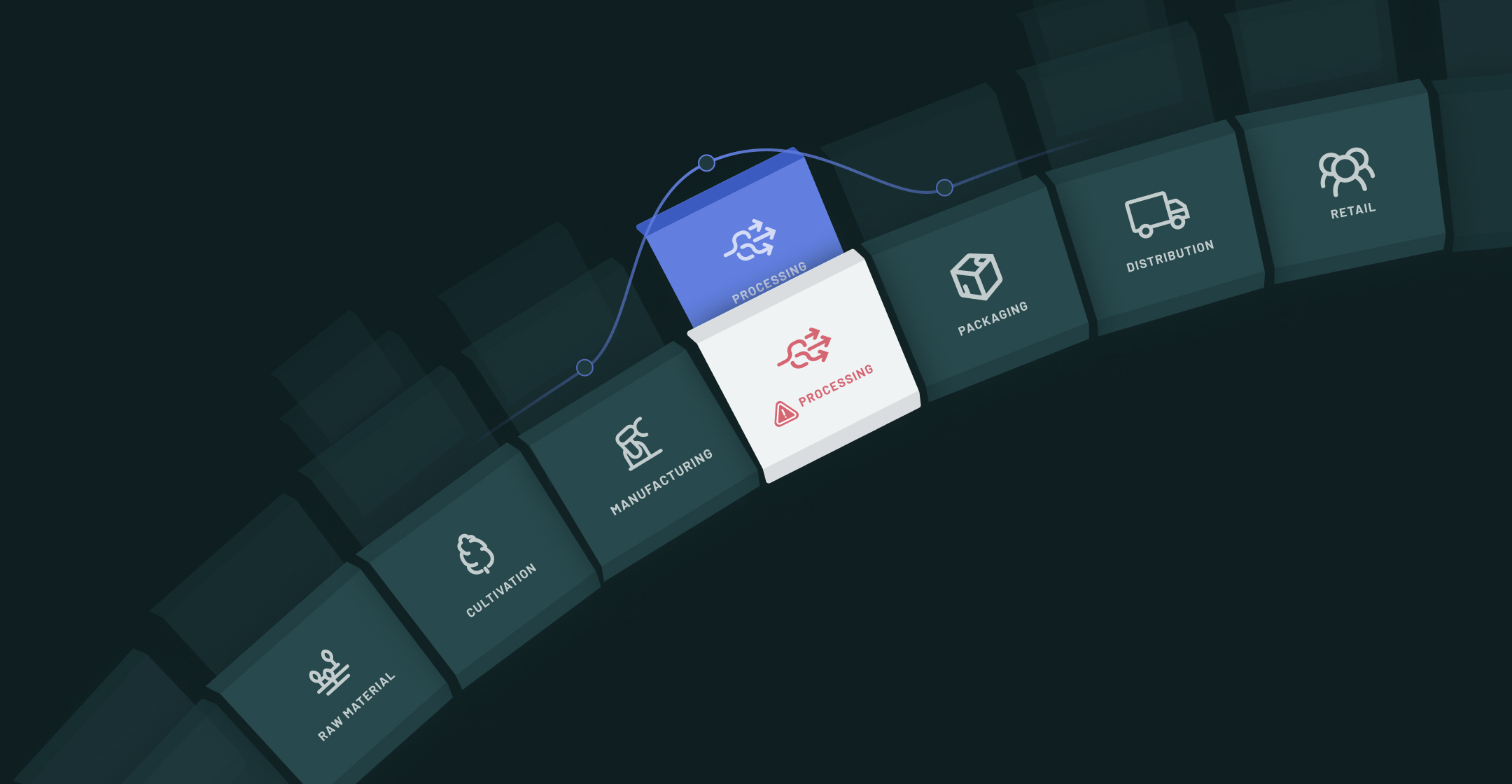

One key tool in this process is the implementation of an operational software system such as Backbone which ensures consistent adherence to GMP standards as well as auditing and compliance reporting. Many hemp extraction facilities are still operating using spreadsheets or even worse manual reporting on pen and paper. These manual, error-prone practices are a thing of the past. In the words of the great NHL legend, Wayne Gretzky “Skate to where the puck is going, not to where it is.”

Still on spreadsheets? We can help."