March 30, 2021

•7 min read

Interview: Gauging Productivity with Humboldt Terp Council

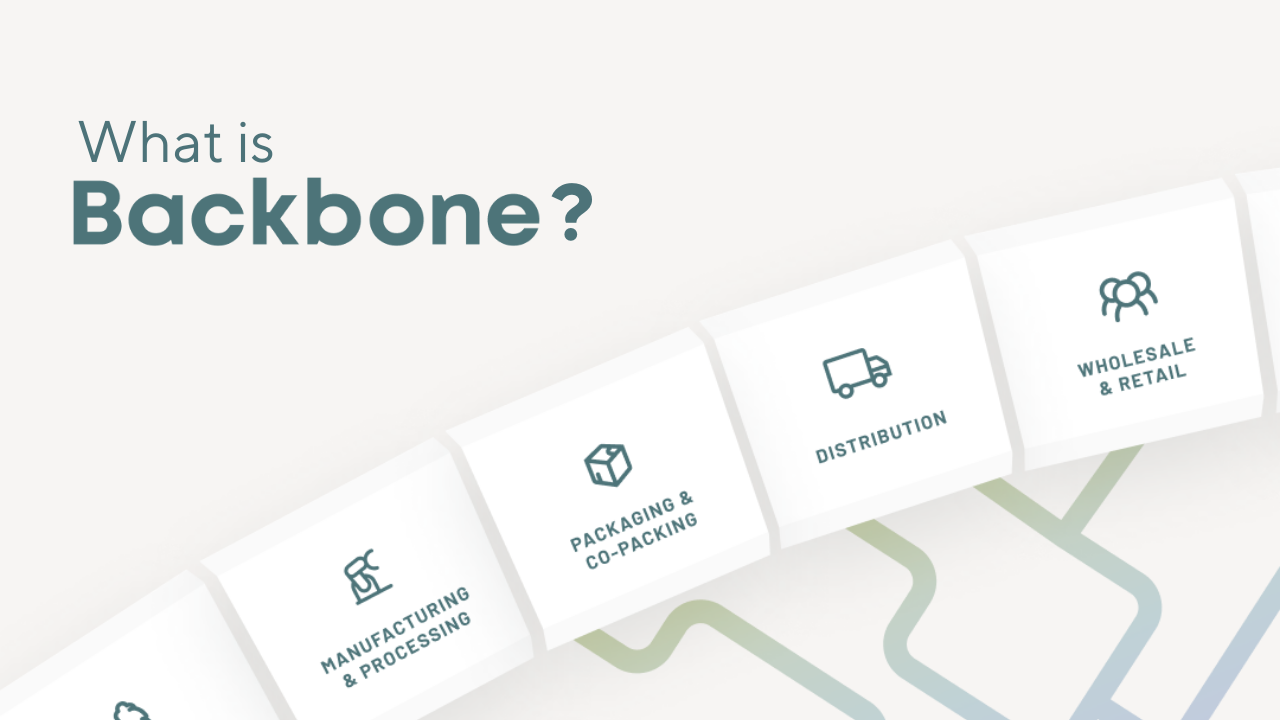

Productivity can mean the difference between wild success and closing up shop. Cannabis businesses know all too well that regulation is messy, competition is fierce, and expected values are high. So how is an entrepreneurial cannabis business to be successful in this ever-changing market? Keep close eye on quality, scalability, and most important, productivity. We had the chance to catch up with Robert Gale, co-founder of Humboldt Terp Council, for an in-depth look.

Tell us about you and Humboldt Terp Council.

I’m Robert Gale, the Extract Manager and Co-Founder of Humboldt Terp Council. We have a pretty small team of three owners and two employees. We started the process towards legalization within the medical community and have been involved with legal recreational manufacturing since day one, back when Proposition 64 was implemented. We’re based in Arcata, CA and do both butane and ice water extraction. When we were first starting out, we fumbled our way through the business side of things with a combination of spreadsheets and Metrc. Eventually, we became early Backbone adopters to help us bridge that gap.

How did you get into the industry?

I was initially a smoker, then became a grower, and eventually started the first delivery dispensary in Arcata. I got into making hash because that was the part of cannabis that I enjoyed the most. We saw an opportunity with medical legalization, and figured this was our chance to push forward and share our passion for quality products on a larger scale.

What do you love about working in cannabis?

I like a lot of aspects of the growing community. I’ve been able to maintain relationships with farmers that I’ve known over the years and have now also entered the legal market. I also enjoy taking plants from a field and turning them into hash in a jar — you can actually see your progress, and there’s a sense of accomplishment with that. Sometimes I reflect and think, “Wow, I’m part-owner of a weed company in California.” It’s easy to overlook, but that really means something. It’s not what I expected for myself, but I’m happy to have made it to this place.

What’s your biggest pain point?

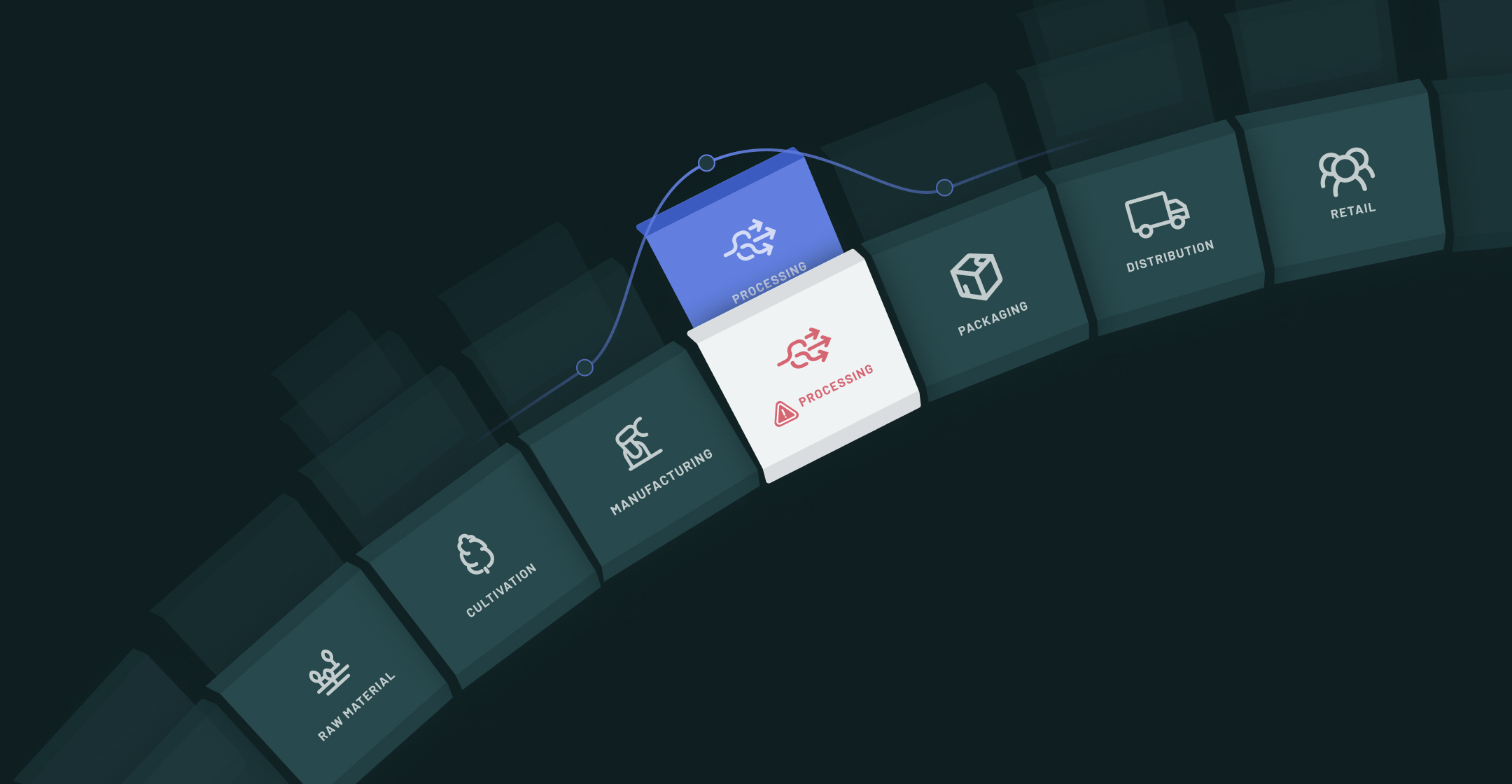

The chain of custody between production, testing, packaging, and distribution is just such a clumsy process. Some of the regulations in place just don’t make sense for the industry. There’s a certain level of arrogance out of Sacramento — every step of the way, they’ve failed to really tap into people that live, eat, and breathe cannabis. Only the giant Democratic machine in California could take something that was humming along without any oversight and grind it down into something that’s becoming more and more like big agriculture. Small businesses have always been at the heart of cannabis, but now they’re under the thumb of excessive regulation, taxation, and lack of understanding. It’s an interesting time, and it seems like we’re moving full-steam ahead towards becoming a mass-market agricultural product.

Tell us about your process.

We start by visiting a farm to check out their production and select a few varieties. As a small business, we’re often out there to actually harvest the plants once they reach peak maturity. We do a fairly light process of removing the fan leaves and clipping the buds off the stems in a traditional hash method. We aim to freeze everything within 30 minutes of harvest and still use an old-fashioned chest freezer — nothing fancy. There are a few differences if we’re harvesting the plants for butane or water hash; we tend to be a little gentler with the water hash because we’re trying to keep the trichome heads intact, whereas with butane we’re melting them, so it doesn’t really matter. For the water hash, we take the frozen flowers and load them into a vessel with water and ice, which separates the trichome heads and carries them off to be sorted. We let the water drain naturally, and then use a freeze dryer to ensure it’s totally dried. The process for butane hash is actually pretty similar. We add the frozen flowers to a vessel and then introduce butane, which melts the trichome heads. The oil is transferred to a receiving vessel and then dried with a scientific vacuum oven. They then both go through a curing process, similar to wine, which can last anywhere one week to two months, depending on the style that we’re making. We’re all hash connoisseurs, and this is how we make what we like to smoke. The best of the best is when you take the same premium flowers that could have been dried and run them through this process. It’s more expensive, but the end result is worth it. If we have good starting material, we’re able to consistently make a good product.

How do you tell if it’s going well?

Our number one goal is to make sure we don’t produce more than we can sell. A lot of manufacturers fall into the trap of wanting to just keep producing, regardless of what their brand can sell. It’s a very tough, competitive market in California because the state is so good at large agriculture. We’ve tried to maintain a higher-priced, higher-end product by not overproducing and sticking with the top one percent of what’s available. We want to avoid the race to the bottom mentality that’s so pervasive when you get into toll processing or white labeling. Success to us is making sure we’re able to maintain the high caliber of product that we like to enjoy ourselves.

What are the red flags you look for during processing?

Trust your nose. You can tell a lot by the smell, even when the flower is frozen. It shouldn’t be scentless, but you want to avoid anything that smells like rot. Degradation can occur if something was frozen, thawed, and was refrozen. Smoke damage is also becoming more common and smells like you’re hanging out at a bonfire. Those are the main things that we look for when taking in a material, especially if we weren’t there to harvest.

How do you measure the productivity of your employees?

We have two operators on our team and two shifts each day. I know how many runs we should be able to complete in each shift if all of the materials needed are on-hand. It differs by variety, but we generally know what we can produce per run. The simple math of how much material goes into a run, how many runs we can complete per day, and how much output we should get gives us the information needed to gauge performance and do some forecasting. We try not to over-complicate things.

Do you have any tips for people who are just beginning to build out their processes?

It’s a tough business to get into right now. My advice is different based on where you’re at in the cannabis food chain. For cultivators, I’d recommend growing for an established brand. If you’re a manufacturer, focus on owning your cultivation and distribution. Distributors need to have a lot of money behind them to really get established. I think getting into retail is a great way to go. Most dispensaries have a monopoly on their market — it’s a good racket, as far as I can tell. Manufacturing as a stand-alone is the worst. There’s no transport-only license for a manufacturer, so we can’t pick up or drop off anything. When you have a Type 7 license, you’re like a cool little island that people want to visit. But if the cruise ship doesn’t stop there, it’s a very precarious place to be. We’re moving towards a more vertically-integrated situation, which is really the only way to survive.